For the second year, the annual Luton Lunch took place at the Putteridge Bury events centre. Organised by Alastair Hay, it was a lovely gathering of Feltmakers, milliners and Luton businesspeople; an essential ‘coming together’ to celebrate and remind ourselves of the importance of this town to the hat trade; for the many years of production of ladies’ millinery and straw braid, not forgetting, the Luton boater.

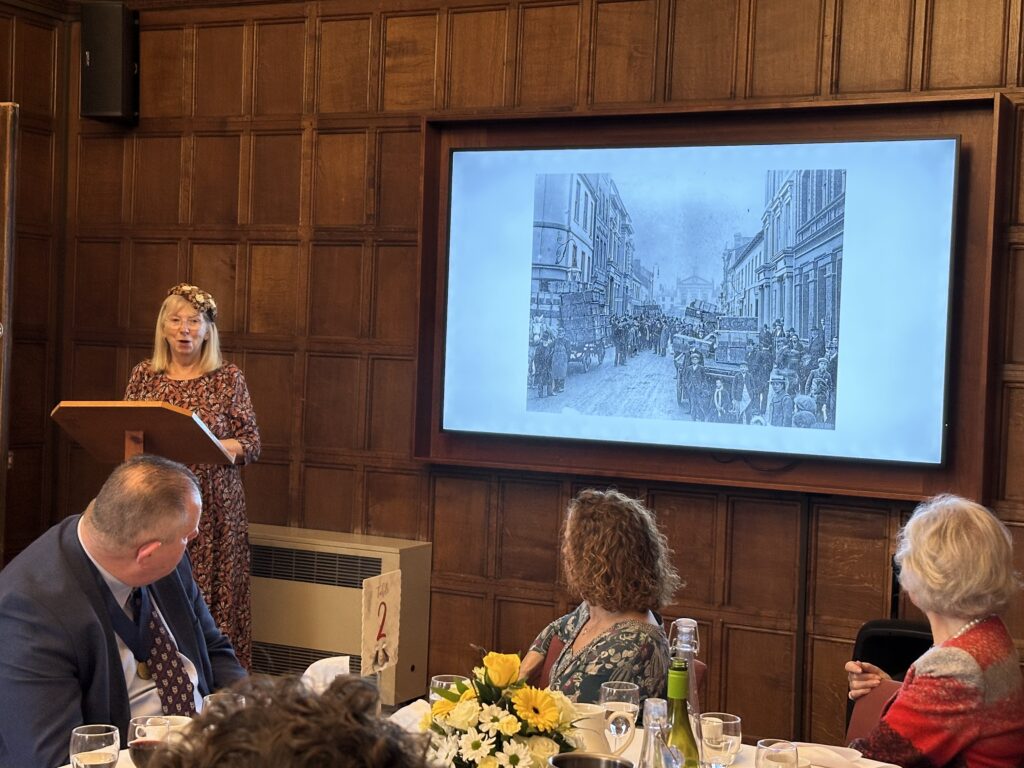

Although a somewhat smaller gathering than previous years, it was easier to circulate and meet likeminded Feltmakers. A luncheon is always special, but we were also an enthusiastic audience for the talk by Veronica Main MBE, our guest speaker, whose knowledge and expertise on straw plait, especially in the Luton area, is acknowledged worldwide.

Veronica is a passionate supporter of Luton’s hat industry and stepping aside from her work in historic and modern-day straw plaiting, she spoke of the enormous role Luton had played in the international hat trade, the prominence it held in the worldwide industry, the skills and design ability of its workers, and the vision, at that time, that this thriving industry would continue forever.

But times change, fashion moves on, China wakes up to cheap hat production, and within a generation or two the industry is reduced dramatically. Veronica’s passionate talk about retaining the skills here in Luton was in no doubt. And yes, Luton is in crisis insomuch as there are only now a handful of factories. But it still retains one of the best dyers, the most skilled blockmaker and a number of raw material specialists.

Young people running hat businesses in Luton are few but they are still here and serve a vital part of the industry. Maybe large-scale manufacturing is past, but small companies and bespoke designers are thriving in the UK and abroad – and it is these people who come to Luton regularly for their goods and services. Veronica pleaded with her audience to support Luton, to uphold its traditions in the hat making world, and keep its presence here. Let us all hope this can be done, to turn the tide of this very precious jewel in the hat making world.

Following her talk, I asked Veronica what were the most industrious years for the hat making/straw plaiting industry in the Luton area?

‘In 1894, there were at least 515 hat manufacturers and 138 allied trades supplying everything from boxes to millinery trimmings and of course all the block makers, blockers, bleachers and dyers.

Sadly, there are no figures for turnover then.

The pre-WW1 years were the most industrious, when hats were still necessary for everyday wear, and the manufacturers had a healthy felt trade, and fabric trade alongside the straw. In 1937, the town employed more than 13,000 people in the hat industry.

Luton was revered around the world for the ability to produce the required volumes for the sales outlets, the quality and ability to quickly copy the latest fashion trends’.

Even in 1996 there were 25 manufacturers and 6 allied companies, and 1,500 people working in the trade. The sales in 1988 were £61million, that is £209 million in today’s money.

Following the luncheon, I also asked the four milliners who had attended how they valued Luton in their present-day businesses, and these were their replies…

Rebecca Gray – Following extensive training Rebecca is today milliner to the Giffords family Circus, a position she has held for almost 3 years. When asked about her dependence on Luton, she said…….

I do indeed buy goods from Luton, including from Baxter’s, Randall Ribbons, Boone and Lane, and Fred Rueggar (when he was around). I generally prefer to see and touch fabrics and supplies before buying them, as you never know what you’re getting with a blind purchase. That’s why I like to make a trip to Luton in person—though you always end up spending more! I also always enjoy the human interaction, exchange and advice you get in person, as it helps establish a relationship with the suppliers.

The trim and wire on the hat I wore today was purchased from Luton, (Randall Ribbons and Baxter’s) while the felt came from Petershams, as at that time they had huge cones, and I specifically wanted large ones. I do love the quality of Baxter’s and the Aladdin’s cave of Randall Ribbons.

Mya Green had formal training in hat making. She now makes to order and also works for the specialist hat shop ‘Mad Hatter & Friends’ in Brighton.

How often do you come to Luton?

About 5 times a year. I’m lucky as I can get the train straight from Brighton!

Do you buy any goods or services from Luton?

Yes. I mainly buy from Luton based firms. Baxter Hart, Randall’s, Boon and Lane and The Trimming Company.

You work in a hat shop in Brighton, do they stock hats made in Luton (from Whiteley, for instance?)

Yes, we do. Lucy always stocks Whiteley (she’s very loyal to them) sometimes stocks Snoxell.

Did the felt or trim of the hat you are wearing come from Luton?

The felt of my hat was bought in Luton (Baxter Hart) along with sinamay which lined the inside (Randalls).

Would you be in crisis if there was no industry in Luton?

YES definitely – most milliners are small independents who need access to materials that are easy to get hold of and to be able to visit to choose in the flesh to check the quality and be inspired. You cannot always do this on line. Boon and Lane are essential as they have the skills and experience to provide blocks created for designers and are accessible to visit and discuss directly. All of the millinery businesses in Luton provide great service. It is wonderful to have a central base so that we can visit many companies on our trips. Milliners are scattered far and wide so this makes it worth the travel.

It would be devastating to the millinery industry without Luton. If it didn’t exist or keeps dwindling it would mean we wouldn’t have access to materials instantly and would not be able to fulfil orders as it may take months to track materials.

Victoria Carson produces a commercial, wholesale range each season. She has taken part in trade exhibitions in Harrogate over the past few years, and has considered Paris, but this is a rather costly option at this time.

Usually, I or a member of my team, will visit suppliers in Luton once per month as most of our materials are purchased from suppliers in Luton – felts, sinamay, feathers, straws, petersham ribbon, crin, veiling, etc.

Did the felt or trim of the hat you are wearing come from Luton?

Yes, it is a peachbloom felt trilby with crin detail. All purchased from Luton.

Would you be in crisis if there was no industry in Luton?

100% I’m very proud to say that I choose to purchase all of my materials from Luton to support the industry.

Chloë Scrivener has worked for many of the top UK milliners, including Philip Treacy, has taught at a high skills level, and is just about to begin a PhD in Millinery.

When you were making regularly how often did you come to Luton?

I usually placed orders over the phone as I quite often knew what I needed / wanted to order, and this would allow me more time for the process of making. However, I would aim to visit Luton several times a year to keep up to date with everything.

What did you buy – blocks, goods or services from Luton?

My main purchases have been from Baxter, Hart and Abraham Ltd for millinery goods and supplies.

Did any of the materials in the headband you are wearing come from Luton?

The black buckram base, millinery wire and the petersham ribbon.

Would you be in crisis if there was no industry in Luton?

I think it would a shame for us to lose the hat industry in Luton, we should try to recognise the importance and significance of what these suppliers have contributed to the hat business and what they have given to the heritage of the hat industry.

Carole Denford

Comments are closed